A Description of Thermocouple:

A thermocouple is a type of temperature sensor that consists of two dissimilar metallic wires joined at one end, creating a junction. When the junction is heated or cooled, it generates a small voltage (known as the Seebeck voltage) that is proportional to the temperature difference between the junction and the other ends of the wires, which are kept at a reference temperature. This voltage can be measured and converted into a temperature reading.

Key Features of Thermocouples:

Construction:

- Typically made of two different metals (e.g., copper and constantan, iron and constantan, or nickel and chromium).

- The junction where the two metals meet is referred to as the "measuring junction," while the other ends are connected to a measuring device and are typically maintained at a known reference temperature (often called the "reference junction").

Types:

Thermocouples are classified into different types based on the materials used, such as:

- Type K (Chromel-Alumel)

- Type J (Iron-Constantan)

- Type T (Copper-Constantan)

- Type E (Chromel-Constantan)

- Type N (Nicrosil-Nisil), etc.

Each type has specific temperature ranges and characteristics suited for different applications.

Temperature Range:

Thermocouples can measure a wide range of temperatures, from cryogenic levels (like Type T) to very high temperatures (like Type B, which can measure up to 1,800°C or higher).

Response Time:

Thermocouples typically have a fast response time, making them suitable for dynamic temperature measurements.

Advantages:

Simple construction and ruggedness.

Wide temperature range and availability in various configurations.

Relatively low cost and ease of installation.

Limitations:

Accuracy can be affected by factors such as calibration, wire insulation, and the quality of the connections.

The output

Type for Sheath Wire Type K:

| Product Name |

Code |

Type |

Shaeth Material |

Outside Dia. |

Temperature |

| NiCr-NiSi /NiCr-NiAl |

KK |

K |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| SS310 Inconel600 |

0.5-1.0 |

500 |

| 1.5-3.2 |

800 |

| 4.0-6.4 |

900 |

| 8.0-12.7 |

1000 |

| NiCrSi-NiSi |

NK |

N |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| SS310 Inconel600 |

0.5-1.0 |

500 |

| 1.5-3.2 |

800 |

| 4.0-6.4 |

900 |

| 8.0-12.7 |

1000 |

| NiCr-Konstantan |

EK |

E |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| Fe-Konstantan |

JK |

J |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| Cu-Konstantan |

TK |

T |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| RhPt10-Ph |

SK |

S |

Inconel600 |

6.0-12.7 |

1100 |

Different temperature measuring media and service conditions have an impact on the service life and temperature range of armored thermocouples, the data in the table is only recommended data.

Accuracy for Sheath Wire Type K

| Type |

Class I |

Class II |

| Accuracy |

Temp.Range |

Accuracy |

Temp.Range |

| K |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-1000℃ |

±0.75% |

375℃-1000℃ |

| N |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-1000℃ |

±0.75% |

375℃-1000℃ |

| E |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-800℃ |

±0.75% |

375℃-800℃ |

| J |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-800℃ |

±0.75% |

375℃-800℃ |

| T |

±0.5℃ |

-40~125℃ |

±1.0℃ |

-40~125℃ |

| ±0.4% |

125℃-350℃ |

±0.75% |

125℃-350℃ |

| S |

0-1100℃ |

±1.0℃ |

0-1100℃ |

±1.5℃ |

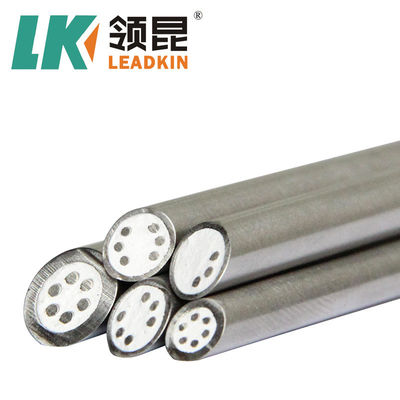

Product Description:

- The Mineral-Insulated Thermocouple Wiring is available in different sizes, ranging from 0.5mm to 4.0mm, and can be used to measure temperatures up to 1200°C. The conductor type can be either solid or stranded, depending on the application requirements. The insulation used in the Mineral-Insulated Thermocouple Wiring is mineral insulated, which provides excellent electrical insulation and mechanical protection, ensuring the cable's durability and reliability.

- The sheath of the Mineral-Insulated Thermocouple Wiring is made from stainless steel, making it suitable for use in harsh environments. The stainless steel sheath provides excellent resistance to corrosion and high temperatures, making it ideal for use in applications where the cable is exposed to chemicals, moisture, and extreme temperatures.

- The Mineral-Insulated Thermocouple Wiring is available with different connector types, including screw, plug, and socket. The connector type can be selected based on the application requirements. For instance, the screw connector type is suitable for applications where the cable needs to be connected and disconnected frequently. The plug and socket connector types are ideal for applications where the cable needs to be connected permanently.

- The Mineral-Insulated Thermocouple Wiring is highly reliable and accurate, making it ideal for use in various industrial applications such as chemical processing, food processing, and pharmaceuticals. It is designed to perform under extreme conditions, making it suitable for use in harsh environments. The Mineral-Insulated Temperature Coil is also widely used in research and development applications where high accuracy and reliability are essential.

Applications :

RTD and Thermocouple Sensors Constructed Using MI Cable are Used Extensively in Various Applications such as:.

- Solid waste incinerators.

- Sintering powdered metals.

- Firing ceramic materials.

- Gas or oil fired furnaces.

- Fuel fired heat exchangers.

- Box furnaces.

- Nuclear or hydrocarbon based energy plant.

Product Pictures:

Company Information:

A. Main Products

B. Package

We add heat shrink tubing and plastic film to make sure high insulated resistance.

Except marking notes, we also have pass card and test report for every coil cable.

C. Mi cable Production line

We have high - quality professional products, as well as advanced product lines and equipments. All of the products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.Along the increasing market demands, we continuously satisfy customers by updating products to improve prouduction systems, improve quality.

Support and Services:

Our Mineral Insulated Thermocouple Cables are designed to provide accurate temperature measurements even in high-temperature environments. With a variety of options for thermocouple types, sheath materials, and insulation materials, we offer a custom solution to fit your specific needs. Our cables are also highly durable and resistant to vibration and shock.

We provide technical support and services for our Mineral Insulated Thermocouple Cables, including:

- Selection guidance for thermocouple type, sheath material, and insulation material

- Assistance with cable installation and maintenance

- Troubleshooting and problem-solving

- Repair and warranty services

Our team of experts is dedicated to ensuring the highest level of customer satisfaction and providing reliable solutions for your temperature measurement needs.

Order Notice:

1. Accurate quotation.

2. Confirm the price, trade term, lead time, payment term etc.

3. LEADKIN sales send the Proforma Invoice with LEADKIN seal.

4. Customer arranges the payment for deposit and sends us bank slip.

5. Middle Production-send photos to show the production line which you can see your products in . Confirm the estimated delivery time again.

6. End Production-Mass production products photos.

7. Clients make payment for balance and LEADKIN ships the goods. Inform the tracking number and check the status for clients.

8. The order is finished perfectly when you receive the goods and get satisfied with them .

9. Feedback to LEADKIN about Quality , Service, Market Feedback & Suggestion. And we will do better .

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!