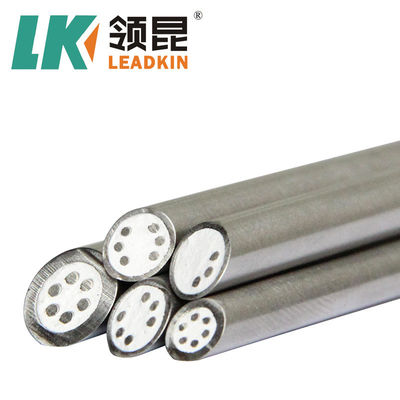

Quick Details:

Type: K/N/E/J/T/S/R/B

Place of Origin: Zhejiang, China (Mainland)

Accuracy: I-0.4%t, II-0.75%t, III-1.5%t

Core number: 2,3,4,6

Inorganic mineral insulating lead material: Ni, Cu

Insulator: 99.6% high purity MgO

Certificate:ISO9001, IATF16949, CE

Application: connecting with thermocouple and instrument machine

Sheath material: 0Cr18Ni10Ti, SS304S,SS316L,SS316, Cu

Sheath Dia(mm): φ3.0, φ4.0, φ6.0, φ8.0

Type for Sheath Wire Type K:

| Product Name |

Code |

Type |

Shaeth Material |

Outside Dia. |

Temperature |

| NiCr-NiSi /NiCr-NiAl |

KK |

K |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| SS310 Inconel600 |

0.5-1.0 |

500 |

| 1.5-3.2 |

800 |

| 4.0-6.4 |

900 |

| 8.0-12.7 |

1000 |

| NiCrSi-NiSi |

NK |

N |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| SS310 Inconel600 |

0.5-1.0 |

500 |

| 1.5-3.2 |

800 |

| 4.0-6.4 |

900 |

| 8.0-12.7 |

1000 |

| NiCr-Konstantan |

EK |

E |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| Fe-Konstantan |

JK |

J |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| Cu-Konstantan |

TK |

T |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| RhPt10-Ph |

SK |

S |

Inconel600 |

6.0-12.7 |

1100 |

Different temperature measuring media and service conditions have an impact on the service life and temperature range of armored thermocouples, the data in the table is only recommended data.

Accuracy for Sheath Wire Type K

| Type |

Class I |

Class II |

| Accuracy |

Temp.Range |

Accuracy |

Temp.Range |

| K |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-1000℃ |

±0.75% |

375℃-1000℃ |

| N |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-1000℃ |

±0.75% |

375℃-1000℃ |

| E |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-800℃ |

±0.75% |

375℃-800℃ |

| J |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-800℃ |

±0.75% |

375℃-800℃ |

| T |

±0.5℃ |

-40~125℃ |

±1.0℃ |

-40~125℃ |

| ±0.4% |

125℃-350℃ |

±0.75% |

125℃-350℃ |

| S |

0-1100℃ |

±1.0℃ |

0-1100℃ |

±1.5℃ |

About this product:

Applications

Industrial: Used in furnaces, kilns, gas turbines, and other high-temperature applications.

HVAC: Employed in heating, ventilation, and air conditioning systems for temperature control.

Automotive: Used in exhaust gas temperature measurements and engine monitoring.

Food Industry: Monitors temperatures in cooking and processing environments.

Advantages and Disadvantages

Advantages:

Wide temperature range.

Simple construction and robust design.

Fast response time and ease of use.

Disadvantages:

Limited accuracy compared to other sensors like RTDs.

Non-linear output requires compensation.

Susceptible to electromagnetic interference.

Safety and Handling

Thermal Shock: Avoid rapid temperature changes to prevent damage.

Corrosive Environments: Use appropriate materials to prevent degradation.

Handling: Handle with care to avoid mechanical damage to junctions and wires.

Maintenance

Regularly inspect and calibrate to ensure accurate readings.

Clean the junction area if contamination is suspected.

Conclusion

Thermocouples are versatile temperature sensors suitable for a wide range of applications. Understanding their operation, types, construction, and proper handling is crucial for effective use in both industrial and laboratory settings.

Automotive cables are specialized electrical cables designed for use in vehicles, including cars, trucks, motorcycles, and other motorized vehicles. These cables are essential for powering electrical systems and components such as lights, sensors, infotainment systems, and battery connections. Here’s an overview of automotive cables, their types, specifications, and applications:

Key Features of Automotive Cables:

Durability: Automotive cables are designed to withstand harsh conditions, including high temperatures, vibrations, moisture, and exposure to chemicals (such as oil and fuel).

Insulation: The insulation materials used in automotive cables are often made from thermoplastic materials like PVC, cross-linked polyethylene (XLPE), or rubber compounds. These materials are chosen for their resistance to heat and chemicals.

Conductor Material: Most automotive cables use copper conductors due to their excellent conductivity. Some may also use aluminum for weight reduction, especially in larger applications.

Stranding: Cables are typically stranded (composed of multiple smaller wires twisted together) to increase flexibility and reduce the risk of breakage due to vibration.

Temperature Ratings: Automotive cables are rated for specific temperature ranges, which can vary depending on their application. For example, under-hood cables must handle higher temperatures than those used in the cabin.

Color Coding: Automotive cables are often color-coded to help identify their function and prevent miswiring during installation.

Applications :

- Solid waste incinerators

- Sintering powdered metals

- Firing ceramic materials

- Gas or oil fired furnaces

- Fuel fired heat exchangers

- Box furnaces

- Nuclear or hydrocarbon based energy plants

- And many more...

Product Pictures:

Company Information:

A. Main Products

B. Package

We add heat shrink tubing and plastic film to make sure high insulated resistance.

Except marking notes, we also have pass card and test report for every coil cable.

C. Mi cable Production line

We have high - quality professional products, as well as advanced product lines and equipments. All of the products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.Along the increasing market demands, we continuously satisfy customers by updating products to improve prouduction systems, improve quality.

The FAQ:

1. How do you install a thermocouple?

Installation involves:

Ensuring proper junction placement where temperature measurement is needed.

Using appropriate wire types and connectors to prevent errors.

Calibrating the thermocouple with known temperature references if necessary.

2. What is reference junction compensation?

Reference junction compensation is the process of accounting for the temperature at the connection point of the thermocouple wires (where they connect to the measuring device). This is crucial for accurate temperature readings, as the voltage produced is influenced by the temperature at this junction.

3. How do you read a thermocouple?

Thermocouples typically require a temperature measuring instrument (like a thermocouple reader or data logger) that converts the generated voltage into a temperature reading based on the type of thermocouple used and its calibration.

Order Notice:

1. Accurate quotation.

2. Confirm the price, trade term, lead time, payment term etc.

3. LEADKIN sales send the Proforma Invoice with LEADKIN seal.

4. Customer arranges the payment for deposit and sends us bank slip.

5. Middle Production-send photos to show the production line which you can see your products in . Confirm the estimated delivery time again.

6. End Production-Mass production products photos.

7. Clients make payment for balance and LEADKIN ships the goods. Inform the tracking number and check the status for clients.

8. The order is finished perfectly when you receive the goods and get satisfied with them .

9. Feedback to LEADKIN about Quality , Service, Market Feedback & Suggestion. And we will do better .

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!