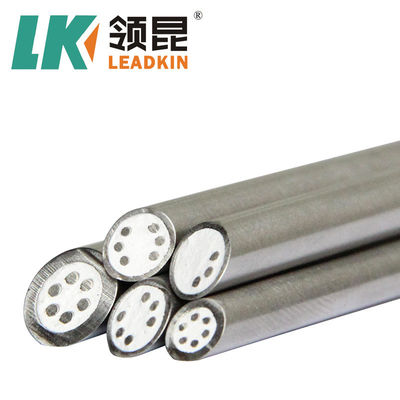

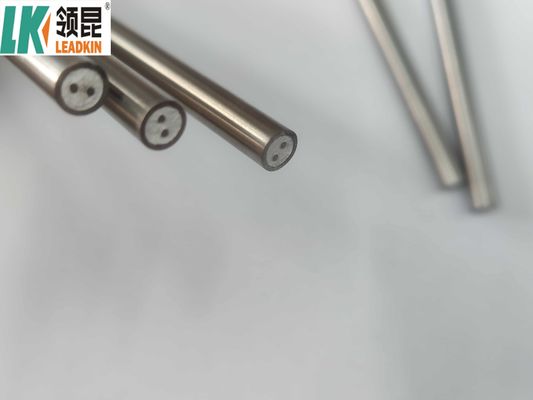

3 Core Mineral Insulated Metal Sheathed Cable With 4.0-8.0mm

Product Specifications

| Core |

2,3,4,6 |

| Insulation |

MgO |

| Warranty |

1 Year |

| Temperature Range |

200℃-1000℃ |

| Accuracy |

Class I, II, III |

| Outside Dia |

0.5-12.7mm |

| Package |

Carton, Pallet |

| Function |

Temperature test |

| Cable Length |

1-5m or Customized |

| Thermocouple Type |

K/N/E/J/T/S/R/B |

Product Details

Quick Details

Type: K/N/E/J/T/S/R/B

Place of Origin: Zhejiang, China

Accuracy: I-0.4%t, II-0.75%t, III-1.5%t

Core number: 2,3,4,6

Inorganic mineral insulating lead material: Ni, Cu

Insulator: 99.6% high purity MgO

Certificate: ISO9001, IATF16949, CE

Application: Connecting with thermocouple and instrument machine

Sheath material: 0Cr18Ni10Ti, SS304S, SS316L, SS316, Cu

Sheath Dia(mm): φ3.0, φ4.0, φ6.0, φ8.0

Type for Sheath Wire Type K

| Product Name |

Code |

Type |

Sheath Material |

Outside Dia. |

Temperature |

| NiCr-NiSi /NiCr-NiAl |

KK |

K |

SS304 SS316 |

0.5-1.0 |

400 |

|

|

|

|

1.5-3.2 |

600 |

|

|

|

|

4.0-8.0 |

800 |

|

|

|

SS310 Inconel600 |

0.5-1.0 |

500 |

|

|

|

|

1.5-3.2 |

800 |

|

|

|

|

4.0-6.4 |

900 |

|

|

|

|

8.0-12.7 |

1000 |

| NiCrSi-NiSi |

NK |

N |

SS304 SS316 |

0.5-1.0 |

400 |

|

|

|

|

1.5-3.2 |

600 |

|

|

|

|

4.0-8.0 |

800 |

|

|

|

SS310 Inconel600 |

0.5-1.0 |

500 |

|

|

|

|

1.5-3.2 |

800 |

|

|

|

|

4.0-6.4 |

900 |

|

|

|

|

8.0-12.7 |

1000 |

| NiCr-Konstantan |

EK |

E |

SS304 SS316 |

0.5-1.0 |

400 |

|

|

|

|

1.5-3.2 |

600 |

|

|

|

|

4.0-8.0 |

800 |

| Fe-Konstantan |

JK |

J |

SS304 SS316 |

0.5-1.0 |

400 |

|

|

|

|

1.5-3.2 |

600 |

|

|

|

|

4.0-8.0 |

800 |

| Cu-Konstantan |

TK |

T |

SS304 SS316 |

0.5-1.0 |

400 |

|

|

|

|

1.5-3.2 |

600 |

|

|

|

|

4.0-8.0 |

800 |

| RhPt10-Ph |

SK |

S |

Inconel600 |

6.0-12.7 |

1100 |

Note: Different temperature measuring media and service conditions have an impact on the service life and temperature range of armored thermocouples. The data in the table is only recommended data.

Accuracy for Sheath Wire Type K

| Type |

Class I |

Class II |

| K |

±1.5℃ (-40~375℃) |

±2.5℃ (-40~375℃) |

| ±0.4% (375℃-1000℃) |

±0.75% (375℃-1000℃) |

| N |

±1.5℃ (-40~375℃) |

±2.5℃ (-40~375℃) |

| ±0.4% (375℃-1000℃) |

±0.75% (375℃-1000℃) |

| E |

±1.5℃ (-40~375℃) |

±2.5℃ (-40~375℃) |

| ±0.4% (375℃-800℃) |

±0.75% (375℃-800℃) |

| J |

±1.5℃ (-40~375℃) |

±2.5℃ (-40~375℃) |

| ±0.4% (375℃-800℃) |

±0.75% (375℃-800℃) |

| T |

±0.5℃ (-40~125℃) |

±1.0℃ (-40~125℃) |

| ±0.4% (125℃-350℃) |

±0.75% (125℃-350℃) |

| S |

±1.0℃ (0-1100℃) |

±1.5℃ (0-1100℃) |

Product Overview

A thermocouple temperature probe is a type of temperature sensor that uses the thermoelectric effect to measure temperature. It consists of two different metal wires joined at one end, which generates a voltage that corresponds to temperature differences.

Construction

- Wires: Made of two different conductive metals (commonly copper, nickel, chromel, alumel) that form a junction

- Junction: The point where the two wires are joined is called the measuring or hot junction

- Insulation: Wires are insulated with high-temperature materials like ceramic or fiberglass

- Sheath: Entire assembly is encased in a protective metal or ceramic sheath

Working Principle

The Seebeck Effect: When two different metals are joined and exposed to a temperature gradient, a voltage is produced at the junction. This voltage relates to the temperature difference between the hot junction and cold junction.

Types of Thermocouples

- Type K (Chromel-Alumel): -200°C to 1260°C, general-purpose

- Type J (Iron-Constantan): -40°C to 750°C, lower temperature applications

- Type T (Copper-Constantan): -200°C to 350°C, cryogenic applications

- Type E (Chromel-Constantan): -200°C to 900°C, high output voltage

- Type N (Nicrosil-Nisil): -200°C to 1300°C, high-temperature stability

- Type S (Platinum-Rhodium): 0°C to 1600°C, high-precision laboratory use

Applications

- Industrial: Manufacturing processes, furnaces, kilns

- HVAC: Heating, ventilation, and air conditioning systems

- Medical: Patient monitoring devices

- Aerospace: Engine and ambient temperature monitoring

- Food Industry: Cooking temperatures and food safety

- Solid waste incinerators

- Sintering powdered metals

- Firing ceramic materials

- Gas or oil fired furnaces

- Nuclear or hydrocarbon based energy plants

Advantages

- Wide temperature range measurement

- Durable construction for harsh environments

- Fast response to temperature changes

- Relatively inexpensive

- Simple and rugged design

Considerations

- Regular calibration needed for accuracy

- Proper installation critical for accurate readings

- Choose appropriate type based on environmental conditions

- Non-linear output requires calibration

- Reference junction compensation needed for precise measurements

Product Images

Company Information

Main Products

Package

We add heat shrink tubing and plastic film to ensure high insulated resistance. Each coil cable includes marking notes, pass card and test report.

MI Cable Production Line

We have high-quality professional products with advanced production lines and equipment. All products comply with international quality standards and are appreciated in global markets. We continuously improve our production systems and product quality to meet increasing market demands.

Order Process

- Request accurate quotation

- Confirm price, trade terms, lead time, and payment terms

- Receive Proforma Invoice with company seal

- Arrange payment for deposit and send bank slip

- Receive production line photos showing your products

- Receive mass production photos before completion

- Make balance payment and receive shipping details

- Confirm satisfactory receipt of goods

- Provide feedback on quality and service

Frequently Asked Questions

What are the advantages of using thermocouples?

Wide temperature range, fast response time, simple and rugged design, relatively inexpensive, and can be used in various environments including extreme conditions.

What are the disadvantages of thermocouples?

Non-linear output requiring calibration, potentially lower accuracy than other sensors, requires reference junction compensation, and susceptible to electromagnetic interference.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!