Quick Details:

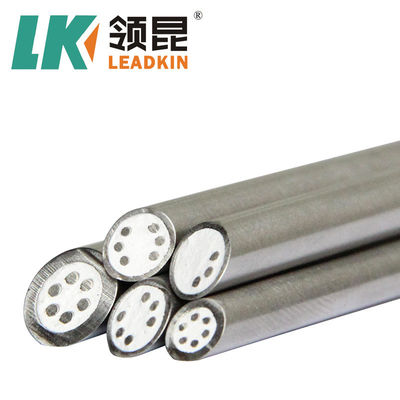

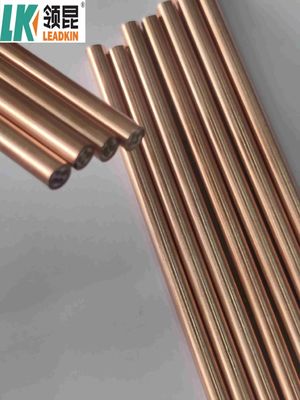

Name:LEADKIN Copper Sheath Compensation Cable Mi Cable

Type: Cu-CuNi

Conductor material: Cu-CuNi

Insulator: 99.6% high purity MgO

Core number: 2, 4

Sheath material: Copper

Dia(mm): 6.0 mm

Application: compensation cable for R B S type thermocouple

Making sample time: 2 days

Type for Copper Cable

| Product Name |

Code |

Type |

Shaeth Material |

Outside Dia. |

Temperature |

| Mi Copper Cable |

1*Cu+1*CuNi |

φ6 |

Copper |

6 |

1100 |

Information for Copper Cable

| Dia |

Type |

Nominal Conductor Dia |

Weight/Meter |

| 6.0 |

Single |

positive:1.06-1.16 Negative:1.3-1.42 |

0.13 |

| Double |

positive:0.96-1.08 Negative:1.22-1.38 |

0.14 |

Mineral Insulated Copper Cable: The Perfect Solution for High Temperature Environments

Mineral Insulated Copper Cable (MICC) is an innovative and highly effective solution for electrical installations, especially in high-temperature environments. Its unique construction and properties make it ideal for various applications where durability, reliability, and safety are paramount. Here’s a closer look at what makes MICC the perfect choice for such demanding conditions.

What is Mineral Insulated Copper Cable?

Mineral Insulated Copper Cable consists of copper conductors surrounded by a mineral insulation material, typically magnesium oxide (MgO). This insulation is encased in a copper sheath, providing robust protection against environmental factors and ensuring long-lasting performance.

Key Features and Benefits

High-Temperature Resistance:

MICC can withstand extreme temperatures, often up to 250°C (482°F) or even higher, making it suitable for environments like industrial furnaces, power plants, and petrochemical facilities.

Fire Resistance:

The mineral insulation is non-combustible and does not emit toxic fumes when exposed to fire. This characteristic significantly enhances safety in case of fire hazards.

Mechanical Strength:

The durable copper sheath provides excellent protection against mechanical damage, making MICC ideal for harsh environments where cables might be subject to physical stress.

Corrosion Resistance:

The copper sheath protects the inner conductors from moisture and corrosive substances, ensuring long-term reliability in chemical processing and marine applications.

Low Electromagnetic Interference (EMI):

MICC minimizes electromagnetic interference, making it suitable for sensitive electronic applications.

Versatility:

It can be used for various applications, including power distribution, instrumentation, and control systems, in sectors such as oil and gas, petrochemicals, and heavy manufacturing.

Long Lifespan:

The robust construction and protective features of MICC lead to a much longer operational lifespan compared to traditional cables, resulting in lower maintenance and replacement costs.

Corrosion-resistant mineral insulated copper cables (MICC) are specifically designed to perform reliably in harsh environments, where exposure to moisture, chemicals, and extreme temperatures can lead to significant deterioration of traditional electrical cables. Here’s a detailed overview of their features, applications, and advantages:

Features of Corrosion-Resistant Mineral Insulated Copper Cable

Construction:

Copper Conductor: The core of MICC is typically made of high-purity copper, offering excellent conductivity and durability.

Mineral Insulation: The insulation is made from inorganic materials (often magnesium oxide) which provide excellent thermal and mechanical properties.

Metal Sheath: A protective metal sheath, usually made of copper or stainless steel, shields the insulation and conductor from external damage and environmental factors.

Corrosion Resistance:

The use of stainless steel or other corrosion-resistant alloys for the outer sheath helps prevent damage from saltwater, chemicals, and other corrosive agents.

The mineral insulation is non-hygroscopic, meaning it does not absorb moisture, preventing corrosion of the copper conductor.

Temperature Rating:

MICC can withstand extreme temperatures, often rated for use in environments ranging from -200°C to +250°C, making them suitable for both cryogenic and high-temperature applications.

Fire Resistance:

Mineral insulated cables are inherently fire-resistant because they do not burn or contribute to the spread of flames. They can maintain circuit integrity even in high-temperature fire situations.

Mechanical Strength:

MICC offers high mechanical strength and resistance to impact, making them ideal for environments where physical damage is a concern.

Product Pictures

Company Information:

A. Main Products

B. Package

We add heat shrink tubing and plastic film to make sure high insulated resistance.

Except marking notes, we also have pass card and test report for every coil cable.

C. Warehouse

We have great amount mi cable in stock. We expecting your visiting.

D. Our Team

FAQ:

| 1. Accurate quotation. |

| 2. Confirm the price, trade term, lead time, payment term etc. |

| 3. LEADKIN sales send the Proforma Invoice with LEADKIN seal. |

| 4. Customer arranges the payment for deposit and sends us bank slip. |

| 5. Middle Production-send photos to show the production line which you can see your products in . Confirm the estimated delivery time again. |

| 6. End Production-Mass production products photos. |

| 7. Clients make payment for balance and LEADKIN ships the goods. Inform the tracking number and check the status for clients. |

| 8. The order is finished perfectly when you receive the goods and get satisfied with them . |

| 9. Feedback to LEADKIN about quality, service, market feedback & suggestion. And we will do better . |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!