When discussing a 3-core mineral insulated cable (MIC) of the K type for thermocouples, specifically in the 4.0-8.0 mm range, there are several key aspects to consider:

Overview of K Type Thermocouples:

K Type Thermocouples: These are made from Chromel (Nickel-Chromium alloy) and Alumel (Nickel-Aluminum alloy) and are one of the most common types due to their wide temperature range (-200°C to 1260°C) and good stability.

Thermocouple Functionality: Thermocouples work by measuring the voltage generated at the junction of two different metals, which correlates to temperature.

Features of 3-Core Mineral Insulated Cable:

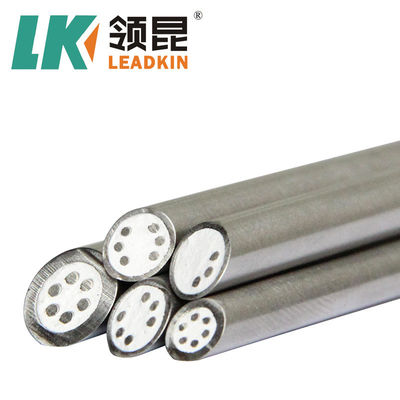

Construction:

Core: The cable contains three conductors, typically two for the thermocouple (Chromel and Alumel) and a third for a reference or compensation wire.

Insulation: The conductors are insulated with mineral insulating material (often magnesium oxide), which allows for high thermal conductivity and excellent dielectric properties.

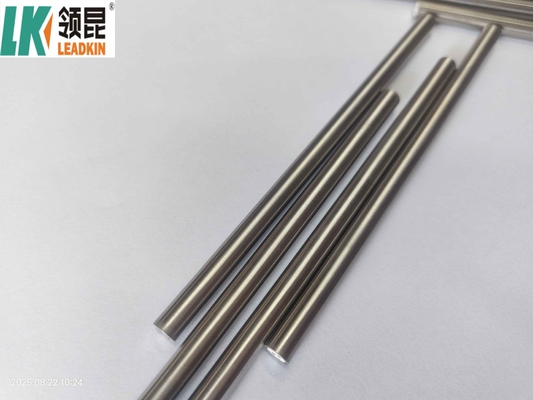

Sheathing: Typically, the cable is sheathed in a metal sheath (such as stainless steel), providing mechanical protection and resistance to corrosion and high temperatures.

Diameter:

4.0-8.0 mm: This indicates the outer diameter of the cable. The choice of diameter affects flexibility, installation ease, and the thermal response time of the thermocouple.

Temperature Range:

Mineral insulated cables can withstand high temperatures, making them suitable for industrial applications.

Applications:

Used in harsh environments, such as furnaces, reactors, and other industrial processes where precise temperature measurement is crucial.

Advantages:

Durability: Resistant to moisture, corrosion, and extreme temperatures.

Response Time: Fast response to temperature changes due to the compact nature of the construction.

Accuracy: High accuracy and stability over a wide temperature range.

Considerations for Use:

Ensure compatibility with the measurement system and calibration.

Consider the environment where the thermocouple will be used, including exposure to chemicals or mechanical stress.

Proper handling during installation is necessary to avoid damaging the cable or its insulation.

We add heat shrink tubing and plastic film to ensure high insulated resistance. Each coil cable includes marking notes, pass card and test report.

We have high-quality professional products with advanced production lines and equipment. All products comply with international quality standards and are appreciated in global markets. We continuously improve our production systems and product quality to meet increasing market demands.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!