Thermocouple K/J/N/T type mineral insulated cable MI thermocouple cable

Mineral insulated M.I. cable thermocouple material is metal sheathed thermocouple wire that contains MgO insulation and is used in the manufacture of thermocouple temperature sensor probes. MIC cable or wire can also be used as extension wire. In harsh environmental conditions, stainless steel sheath MIC or Inconel sheath MIC can be used to protect and transmit instrumentation signals. MIC wire can be supplied in long or short coils, straight lengths and CTL (cut to length) sections for OEM temperature probe building applications. Compacted High Purity magnesium oxide MgO is used to produce cable, wire and temperature probes with special limits of error SLE grade calibration results. MIC cable certification reports are availble for each lot of MIC wire produced. Manufacturers certs can be ordered and shipped with each coil lot of MIC. ANSI wire calibration codes J,K,N,T,E coils of MIC are in stock. This MgO style of thermocouple cable can be used to make nonexpendable thermocouple test sensors.

Quick Details:

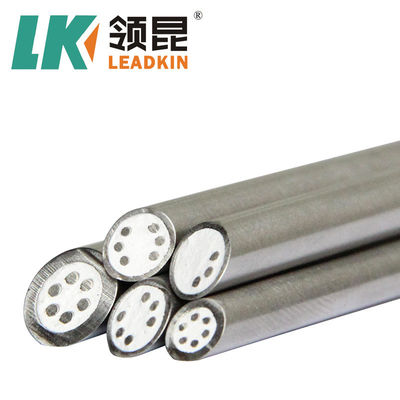

Name:Thermocouple K/J/N/T type mineral insulated cable MI thermocouple cable

Insulator: 99.6% high purity MgO

Core number: 3/4/6

Sheath material: SS321, SS304

Dia(mm): 0.25mm to 12.7mm

Type for Sheath Wire Type K

| Product Name |

Code |

Type |

Shaeth Material |

Outside Dia. |

Temperature |

| NiCr-NiSi /NiCr-NiAl |

KK |

K |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| SS310 Inconel600 |

0.5-1.0 |

500 |

| 1.5-3.2 |

800 |

| 4.0-6.4 |

900 |

| 8.0-12.7 |

1000 |

| NiCrSi-NiSi |

NK |

N |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| SS310 Inconel600 |

0.5-1.0 |

500 |

| 1.5-3.2 |

800 |

| 4.0-6.4 |

900 |

| 8.0-12.7 |

1000 |

| NiCr-Konstantan |

EK |

E |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| Fe-Konstantan |

JK |

J |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| Cu-Konstantan |

TK |

T |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| RhPt10-Ph |

SK |

S |

Inconel600 |

6.0-12.7 |

1100 |

Accuracy for Sheath Wire Type K

| Type |

Class I |

Class II |

| Accuracy |

Temp.Range |

Accuracy |

Temp.Range |

| K |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-1000℃ |

±0.75% |

375℃-1000℃ |

| N |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-1000℃ |

±0.75% |

375℃-1000℃ |

| E |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-800℃ |

±0.75% |

375℃-800℃ |

| J |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-800℃ |

±0.75% |

375℃-800℃ |

| T |

±0.5℃ |

-40~125℃ |

±1.0℃ |

-40~125℃ |

| ±0.4% |

125℃-350℃ |

±0.75% |

125℃-350℃ |

| S |

0-1100℃ |

±1.0℃ |

0-1100℃ |

±1.5℃ |

Product Pictures

Company Information:

A. Our mi cable advantage

Environment-friendly: no pickling clean armored cable

Ultra-high density: nuclear grade 2500mg/cm3

Thick wall thick wire: 40% thicker than the standard of IEC and GB

Solution heat treatment:Improve the strength, hardness, wear resistance, corrosion resistance

B. Mi cable Production line

We have high - quality professional products, as well as advanced product lines and equipments. All of the products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.Along the increasing market demands, we continuously satisfy customers by updating products to improve prouduction systems, improve quality.

1. Assembly

2. Drawing

3. Annealing

4. Polishing

5. Test

6. Mi cable in stock

C. Package

We add heat shrink tubing and plastic film to make sure high insulated resistance.

Except marking notes, we also have pass card and test report for every coil cable.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!