Customized Metal Mineral Insulated Heating Cable Thermocouple Cable

This sheathed mineral-insulated thermocouple wire can be used at high temperatures for prolonged periods with very little drift of the base metal thermocouple. The sheath material uses Nickel-Chrome based sheathing, which provides excellent oxidation resistance. The sheath can withstand long-term exposure to combustion gases or air at temperatures up to1150°C. Short-term exposures to higher temperatures are also possible. Superior resistance to oxidation attack results from a tenacious and protective high temperature film that does not affect the stability of the thermocouple alloys. This film permits the sensor to be used at high temperatures for prolonged periods with improved accuracy over other available sheath materials. The sheathing also provides excellent resistance to corrosion in high temperature chlorine-contaminated oxidizing environments and ammonia/nitride-rich environments at temperatures above 980°C, the temperature at which the protective film forms.

Quick detail

Name:2 Cores Type K Mineral Insulated Thermocouple MI Cable/Wire

Type: K,N,E,J,T,R,B,S,Pt100

Conductor material: NiCr-NiSi, NiCrSi-NiSi), NiCr-Konstantan, Fe-Konstantan, Cu-Konstantan

Insulator: 99.6% high purity MgO

Core number: 2, 4, 6

Sheath material: SS321(SS304), SS316, SS310, Inconel600, Nicrobell

Dia(mm): 0.25mm to 12.7mm

Application: connecting with thermocouple and instrument machine

Place of Origin: Zhejiang, China (Mainland)

Eco-friendly: Yes

MOQ: 100m

Certificate: ISO

Making sample time: all type in stock

Trade term: FOB, EXW, CIF, CFR

Payment term: T/T, Western Union, L/C

Type for Sheath Wire Type K

| Product Name |

Code |

Type |

Shaeth Material |

Outside Dia. |

Temperature |

| NiCr-NiSi /NiCr-NiAl |

KK |

K |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| SS310 Inconel600 |

0.5-1.0 |

500 |

| 1.5-3.2 |

800 |

| 4.0-6.4 |

900 |

| 8.0-12.7 |

1000 |

| NiCrSi-NiSi |

NK |

N |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| SS310 Inconel600 |

0.5-1.0 |

500 |

| 1.5-3.2 |

800 |

| 4.0-6.4 |

900 |

| 8.0-12.7 |

1000 |

| NiCr-Konstantan |

EK |

E |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| Fe-Konstantan |

JK |

J |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| Cu-Konstantan |

TK |

T |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| RhPt10-Ph |

SK |

S |

Inconel600 |

6.0-12.7 |

1100 |

Accuracy for Sheath Wire Type K

| Type |

Class I |

Class II |

| Accuracy |

Temp.Range |

Accuracy |

Temp.Range |

| K |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-1000℃ |

±0.75% |

375℃-1000℃ |

| N |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-1000℃ |

±0.75% |

375℃-1000℃ |

| E |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-800℃ |

±0.75% |

375℃-800℃ |

| J |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-800℃ |

±0.75% |

375℃-800℃ |

| T |

±0.5℃ |

-40~125℃ |

±1.0℃ |

-40~125℃ |

| ±0.4% |

125℃-350℃ |

±0.75% |

125℃-350℃ |

| S |

0-1100℃ |

±1.0℃ |

0-1100℃ |

±1.5℃ |

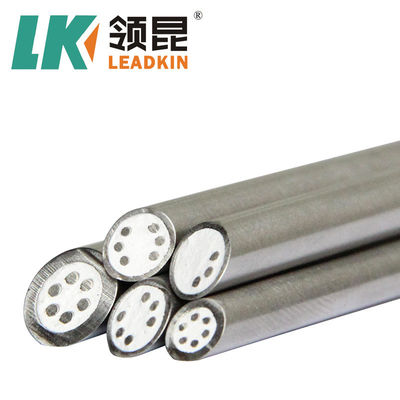

Product Pictures

Order Notice:

| 1. Accurate quotation. |

| 2. Confirm the price, trade term, lead time, payment term etc. |

| 3. LEADKIN sales send the Proforma Invoice with LEADKIN seal. |

| 4. Customer arranges the payment for deposit and sends us bank slip. |

| 5. Middle Production-send photos to show the production line which you can see your products in . Confirm the estimated delivery time again. |

| 6. End Production-Mass production products photos. |

| 7. Clients make payment for balance and LEADKIN ships the goods. Inform the tracking number and check the status for clients. |

| 8. The order is finished perfectly when you receive the goods and get satisfied with them . |

| 9. Feedback to LEADKIN about Quality , Service, Market Feedback & Suggestion. And we will do better . |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!