Mineral Insulated Thermocouple Cable Type K J RTD N S Stainless Steel Sheath

Product description: MI heating cable|MI heat trace cable uses single or multiple alloy heating wires as heat source, high purity, high temperature, fused crystalline magnesium oxide as thermal insulator, seamless continu

Advantages of Mineral Insulated Heat Trace Cables

- Single and dual core series heating resistance cable, magnesium oxide mineral insulated, metal sheath

- High strength

- Heating resistance cable resistance (ohms/m) determines the power output per unit length

- Output power constant, independent of temperature variations

- Maximum working voltage up to 750V

- Output power up to 300W/m (typical max)

- Highest maintain temperature up to 800 ℃

- Maximum exposure temperature up to 1000 ℃

- Hot and cold end fittings are usually prefabricated in the factory

Quick Details:

Name:K Type Surface Thermocouple Temperature Sensor Wire 0-400c

Type: N

Conductor material: NiCrSi-NiSi

Insulator: 99.6% high purity MgO

Core number: 2, 4

Sheath material: SS321, SS316, SS310, Inconel600

Dia(mm): 0.25mm to 12.7mm

Application: connecting with thermocouple and instrument machine

Making sample time: all type in stock

Trade term: FOB, EXW, CIF, CFR

Payment term: T/T, Western Union, L/C

Type for Sheath Wire Type K

| Product Name |

Code |

Type |

Shaeth Material |

Outside Dia. |

Temperature |

| NiCr-NiSi /NiCr-NiAl |

KK |

K |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| SS310 Inconel600 |

0.5-1.0 |

500 |

| 1.5-3.2 |

800 |

| 4.0-6.4 |

900 |

| 8.0-12.7 |

1000 |

| NiCrSi-NiSi |

NK |

N |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| SS310 Inconel600 |

0.5-1.0 |

500 |

| 1.5-3.2 |

800 |

| 4.0-6.4 |

900 |

| 8.0-12.7 |

1000 |

| NiCr-Konstantan |

EK |

E |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| Fe-Konstantan |

JK |

J |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| Cu-Konstantan |

TK |

T |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| RhPt10-Ph |

SK |

S |

Inconel600 |

6.0-12.7 |

1100 |

Accuracy for Sheath Wire Type K

| Type |

Class I |

Class II |

| Accuracy |

Temp.Range |

Accuracy |

Temp.Range |

| K |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-1000℃ |

±0.75% |

375℃-1000℃ |

| N |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-1000℃ |

±0.75% |

375℃-1000℃ |

| E |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-800℃ |

±0.75% |

375℃-800℃ |

| J |

±1.5℃ |

-40~375℃ |

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-800℃ |

±0.75% |

375℃-800℃ |

| T |

±0.5℃ |

-40~125℃ |

±1.0℃ |

-40~125℃ |

| ±0.4% |

125℃-350℃ |

±0.75% |

125℃-350℃ |

| S |

0-1100℃ |

±1.0℃ |

0-1100℃ |

±1.5℃ |

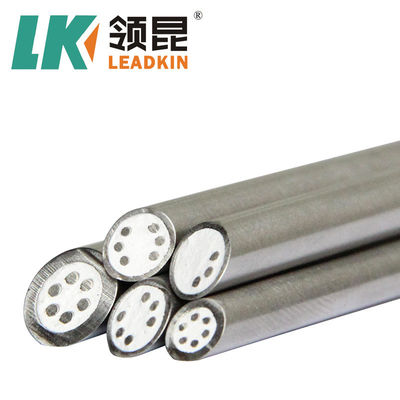

Product Pictures

Company Information:

A. Usage time Test

Armored thermocouple stability test for 6000 hours (250days)

Test 6000 hours under the ceiling temperature 820 ℃, and one time per 500 hours.

Conclusion of cyclic test the thermocouple stability: the life time about 41 years under the 600 ℃ working condition .

B. Mi cable Production line

We have high - quality professional products, as well as advanced product lines and equipments. All of the products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.Along the increasing market demands, we continuously satisfy customers by updating products to improve prouduction systems, improve quality.

1.Assembly

2.Drawing

3.Annealing

4. Polishing

5.Test

6. Mi cable in stock

FAQ:

| 1. Accurate quotation. |

| 2. Confirm the price, trade term, lead time, payment term etc. |

| 3. LEADKIN sales send the Proforma Invoice with LEADKIN seal. |

| 4. Customer arranges the payment for deposit and sends us bank slip. |

| 5. Middle Production-send photos to show the production line which you can see your products in . Confirm the estimated delivery time again. |

| 6. End Production-Mass production products photos. |

| 7. Clients make payment for balance and LEADKIN ships the goods. Inform the tracking number and check the status for clients. |

| 8. The order is finished perfectly when you receive the goods and get satisfied with them . |

| 9. Feedback to LEADKIN about quality, service, market feedback & suggestion. And we will do better . |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!