Quick Details:

Brand: LEADKIN

Type: K, N, E, J, T

Core number: 2, 4, 6

Usage: for thermocouple making

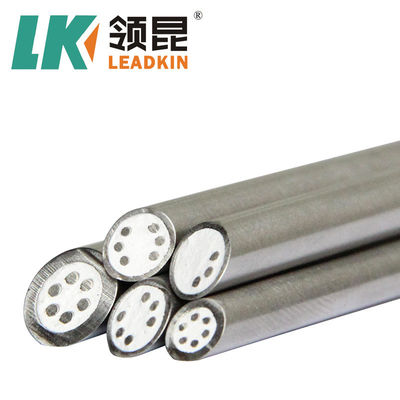

Name: Mineral Insulated Cable

Insulator: 99.6% high purity MgO

Making sample time: all type in stock

Trade term: FOB, EXW, CIF, CFR

Payment term: T/T,Western Union, L/C

Advantage: Competitive price and best service

Application: connecting with thermocouple and instrument machine

Conductor material: NiCr-NiSi,NiCrSi-NiSi), NiCr-Konstantan, Fe-Konstantan, Cu-Konstantan

Sheath material: SS321(SS304), SS316, SS310, INCL600,601, Nicrobell,SS446

Type for Sheath Wire Type K

| Product Name |

Code |

Type |

Shaeth Material |

Outside Dia. |

Temperature |

| NiCr-NiSi /NiCr-NiAl |

KK |

K |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| SS310 Inconel600 |

0.5-1.0 |

500 |

| 1.5-3.2 |

800 |

| 4.0-6.4 |

900 |

| 8.0-12.7 |

1000 |

| NiCrSi-NiSi |

NK |

N |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| SS310 Inconel600 |

0.5-1.0 |

500 |

| 1.5-3.2 |

800 |

| 4.0-6.4 |

900 |

| 8.0-12.7 |

1000 |

| NiCr-Konstantan |

EK |

E |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| Fe-Konstantan |

JK |

J |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| Cu-Konstantan |

TK |

T |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| RhPt10-Ph |

SK |

S |

Inconel600 |

6.0-12.7 |

1100 |

Accuracy for Sheath Wire Type K

| Type |

Class I |

|

Class II |

| Accuracy |

Temp.Range |

|

Accuracy |

Temp.Range |

| K |

±1.5℃ |

-40~375℃ |

|

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-1000℃ |

|

±0.75% |

375℃-1000℃ |

| N |

±1.5℃ |

-40~375℃ |

|

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-1000℃ |

|

±0.75% |

375℃-1000℃ |

| E |

±1.5℃ |

-40~375℃ |

|

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-800℃ |

|

±0.75% |

375℃-800℃ |

| J |

±1.5℃ |

-40~375℃ |

|

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-800℃ |

|

±0.75% |

375℃-800℃ |

| T |

±0.5℃ |

-40~125℃ |

|

±1.0℃ |

-40~125℃ |

| ±0.4% |

125℃-350℃ |

|

±0.75% |

125℃-350℃ |

| S |

0-1100℃ |

±1.0℃ |

|

0-1100℃ |

±1.5℃ |

Product Description

A mineral-insulated (MI) thermocouple cable is a specialized type of cable used for temperature measurement in various industrial applications. It consists of two dissimilar metal wires (typically different alloys) joined together at one end to form a thermocouple junction. The junction is then enclosed within a mineral insulation material, typically magnesium oxide (MgO), which provides electrical insulation and mechanical protection.

The mineral insulation is packed tightly around the thermocouple wires, ensuring good thermal conductivity between the wires and the outer sheath. The outer sheath is usually made of a corrosion-resistant material such as stainless steel or Inconel.

The MI construction offers several advantages for thermocouple applications. It provides excellent resistance to high temperatures, mechanical stress, and environmental hazards. The mineral insulation helps to protect the thermocouple wires from oxidation, contamination, and moisture ingress, ensuring accurate and reliable temperature measurements.

Mineral-insulated thermocouple cables can be customized with different wire materials and sheath sizes to suit specific temperature ranges and environmental conditions. They are commonly used in industries such as petrochemical, power generation, metal processing, and aerospace, where precise and robust temperature measurement is required.

Product Pictures

Company Information:

A. Main Products

B. Package

We add heat shrink tubing and plastic film to make sure high insulated resistance.

Except marking notes, we also have pass card and test report for every coil cable.

C. Exihibition

Product Advantage:

1:High temperature resistance, flexible, anti-corrosion, fast and accurate temperature measurement.

2:High temperature resistant Extension wire.

3:Probe length can be customized, probe can be bent.

4:Arbitrary bending, high temperature resistance, long service life, fast response speed, fixed spring.

5:High Precision Temperature control probe .

6:Quick response.

FAQ:

| 1. Accurate quotation. |

| 2. Confirm the price, trade term, lead time, payment term etc. |

| 3. LEADKIN sales send the Proforma Invoice with LEADKIN seal. |

| 4. Customer arranges the payment for deposit and sends us bank slip. |

| 5. Middle Production-send photos to show the production line which you can see your products in . Confirm the estimated delivery time again. |

| 6. End Production-Mass production products photos. |

| 7. Clients make payment for balance and LEADKIN ships the goods. Inform the tracking number and check the status for clients. |

| 8. The order is finished perfectly when you receive the goods and get satisfied with them . |

| 9. Feedback to LEADKIN about quality, service, market feedback & suggestion. And we will do better . |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!