Quick Details:

Type: K, N, E, J, T

Brand: LEADKIN

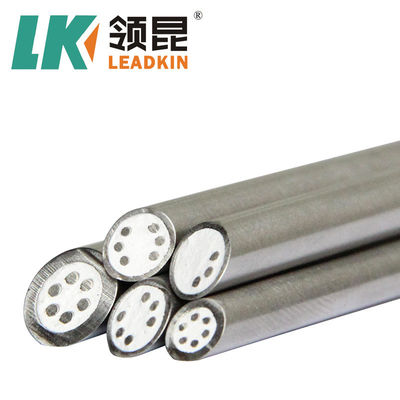

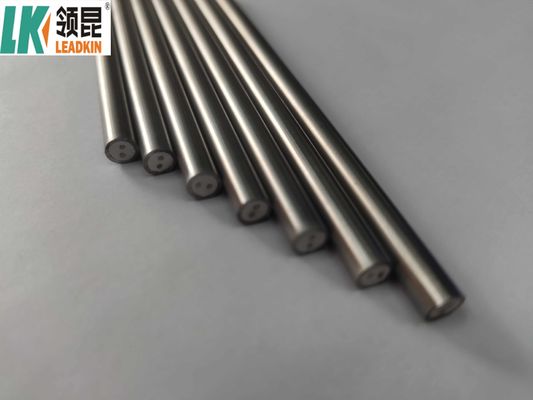

Core number: 2, 4, 6

Dia(mm): 0.5mm to 12.7mm

Usage: for thermocouple making

Insulator: 99.6% high purity MgO

Making sample time: all type in stock

Trade term: FOB, EXW, CIF, CFR

Payment term: T/T,Western Union, L/C

Sheath material: SS321(SS304), SS316

Application: connecting with thermocouple and instrument machine

Conductor material: NiCr-NiSi,NiCrSi-NiSi), NiCr-Konstantan, Fe-Konstantan, Cu-Konstanta

Name:Factory Direct Types 2/4/6/8 Cores Mineral Insulated Cable K/N/E/J/T Mi Cable for Thermocouple

Type for Sheath Wire Type K

| Product Name |

Code |

Type |

Shaeth Material |

Outside Dia. |

Temperature |

| NiCr-NiSi /NiCr-NiAl |

KK |

K |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| SS310 Inconel600 |

0.5-1.0 |

500 |

| 1.5-3.2 |

800 |

| 4.0-6.4 |

900 |

| 8.0-12.7 |

1000 |

| NiCrSi-NiSi |

NK |

N |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| SS310 Inconel600 |

0.5-1.0 |

500 |

| 1.5-3.2 |

800 |

| 4.0-6.4 |

900 |

| 8.0-12.7 |

1000 |

| NiCr-Konstantan |

EK |

E |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| Fe-Konstantan |

JK |

J |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| Cu-Konstantan |

TK |

T |

SS304 SS316 |

0.5-1.0 |

400 |

| 1.5-3.2 |

600 |

| 4.0-8.0 |

800 |

| RhPt10-Ph |

SK |

S |

Inconel600 |

6.0-12.7 |

1100 |

Accuracy for Sheath Wire Type K

| Type |

Class I |

|

Class II |

| Accuracy |

Temp.Range |

|

Accuracy |

Temp.Range |

| K |

±1.5℃ |

-40~375℃ |

|

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-1000℃ |

|

±0.75% |

375℃-1000℃ |

| N |

±1.5℃ |

-40~375℃ |

|

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-1000℃ |

|

±0.75% |

375℃-1000℃ |

| E |

±1.5℃ |

-40~375℃ |

|

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-800℃ |

|

±0.75% |

375℃-800℃ |

| J |

±1.5℃ |

-40~375℃ |

|

±2.5℃ |

-40~375℃ |

| ±0.4% |

375℃-800℃ |

|

±0.75% |

375℃-800℃ |

| T |

±0.5℃ |

-40~125℃ |

|

±1.0℃ |

-40~125℃ |

| ±0.4% |

125℃-350℃ |

|

±0.75% |

125℃-350℃ |

| S |

0-1100℃ |

±1.0℃ |

|

0-1100℃ |

±1.5℃ |

-

Inconel 600 Sheath

- High Temperature Resistance: Exhibits excellent high-temperature performance, capable of withstanding low loads below 1,100°C. Its melting temperature ranges from 1,370–1,430°C.

- Corrosion Resistance: A nickel-chromium-iron-based solid-solution strengthened alloy. The high nickel content provides resistance to many organic and inorganic chemical corrosions, and it is immune to chloride ion stress corrosion cracking. The chromium content offers better corrosion resistance in oxidizing conditions than pure nickel. It can withstand corrosion from chlorine, hydrogen chloride, hydrogen fluoride, etc., making it suitable for thermocouple sheaths in aggressive atmospheres.

- Fabrication and Welding Performance: Features excellent cold/hot working and welding properties. It can be strengthened through cold working and joined by resistance welding, fusion welding, or brazing.

-

SS310 Sheath

- High Temperature Resistance: An austenitic stainless steel with high chromium and nickel content, offering excellent high-temperature strength and stability. It can withstand temperatures of approximately 1,000–1,200°C.

- Corrosion Resistance: Demonstrates good resistance to various corrosive media, particularly in oxidizing acid environments. It effectively prevents corrosion and oxidation in high-temperature, corrosive conditions.

- Fabrication Performance: Easily cold-worked and hot-worked (e.g., rolling, forging, bending) into various shapes and sizes. It also has good weldability and can be joined using common welding methods.

- The mineral insulated thermocouple cable contains two or more thermocouple wires, insulated by magnesium oxide (MgO) powder. When the measuring end senses a temperature change, the thermocouple wires generate a corresponding thermoelectromotive force (EMF). By measuring this EMF, the temperature of the object can be calculated. The Inconel 600 or SS310 sheath protects the thermocouple wires from external factors (e.g., corrosion, mechanical damage, electromagnetic interference), ensuring stable and accurate temperature measurement.

Product Pictures

Company Information:

A. Main Products

B. Package

We add heat shrink tubing and plastic film to make sure high insulated resistance.

Except marking notes, we also have pass card and test report for every coil cable.

C. Exihibition

Product Advantage:

1:High temperature resistance, flexible, anti-corrosion, fast and accurate temperature measurement.

2:High temperature resistant Extension wire.

3:Probe length can be customized, probe can be bent.

4:Arbitrary bending, high temperature resistance, long service life, fast response speed, fixed spring.

5:High Precision Temperature control probe .

6:Quick response.

FAQ:

| 1. Accurate quotation. |

| 2. Confirm the price, trade term, lead time, payment term etc. |

| 3. LEADKIN sales send the Proforma Invoice with LEADKIN seal. |

| 4. Customer arranges the payment for deposit and sends us bank slip. |

| 5. Middle Production-send photos to show the production line which you can see your products in . Confirm the estimated delivery time again. |

| 6. End Production-Mass production products photos. |

| 7. Clients make payment for balance and LEADKIN ships the goods. Inform the tracking number and check the status for clients. |

| 8. The order is finished perfectly when you receive the goods and get satisfied with them . |

| 9. Feedback to LEADKIN about quality, service, market feedback & suggestion. And we will do better . |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!